Uncategorized

CEREAL TECHNOLOGY -RICE

POST HARVEST TECHNOLOGY OF RICE MILLING

…….@ WufasAgronet, We don’t know more than Food.

We earned “FAO” Top Fan barge

RICE (Oryzasativa)

PRE HARVEST –( production details.

Rice is the most widely cultivated Food crop in the world. It constitutes a staple Food for over half of the world population almost 90% of the rice crops is produced and consumed in the Asiatic countries although it has been adopted in a good number of other countries of the world. It can be cultivated from tropics to the temperate climatic conditioning and from sea level to altitude of about 5000 feet.

In Nigeria, Rice production on large scale started during World war 11 and has risen to about millions of metric tons. It is chiefly grown in the North West states of Kebbi, Sokoto,Niger. In North Central states of Kwara, Benue, Adamawa, Taraba. In South West states of Ogun, Ekiti, Oyo and South East states of Ebonyi, Enugu, Anambra, Cross River, etc.

There are two varieties of Rice, The swamp rice and the Upland rice. The swamp rice has to be flooded for a period of 60 -90days during its growth it’s the most important variety and it respond well to good cultivation and treatment given heavier yield. . The Upland is commonly grown in the southern part of the country.

POST HARVEST — Processing

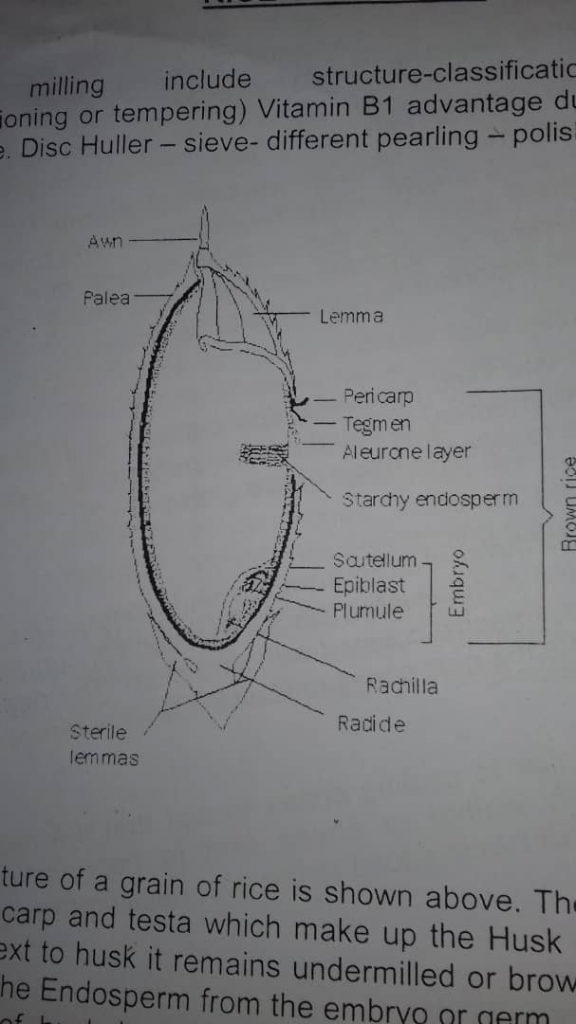

The Structure of a grain of rice is shown in the graphics below. The grain consist of an outer pericarp and testa which makes up the Husk or Hull. The Aleuron layer is next to the husk it’s rich in essential amino acid eg Lysine, Cystine, Methionine, tryptophan, Aginine, minerals and vitamin B.

In Rice milling rice is classified as Hard grain the commercial rice or the Soft grain – has a soft dextrous grain grown and consume locally.

QUALITY

The quality of unmilled rice paddy depends on:

- Size and Shape of grain

- The condition under which it was grown.

- The degree of ripeness.

- Amount of exposure to sun.

The degree of ripeness, Moisture content and conditions of storage affect the behaviour of rice during Milling. Over ripeness and excessive exposure to sun leads to cracks in the grains and causes breakages.

LARGE SCALE MILLING

MOISTURE CONTENT – For satisfactory storage and subsequent milling of the Paddy must not exceed 15%. Rice grown in the tropics is not likely to contain more than this.

CLEANING – In the integrated Rice mills the machines used for cleaning rice paddy are similar to those used for wheat or barley malt. Passing through various screens removing large particles, Straw and strings while other screens with smaller perforations allows rice to pass but removes sand and dust. The rice then flows in thin layer into channels where current of air carries away dead grains and light impurities. Finally magnetic separators removes metallic particles that may cause spark that could result in dust explosion.

PARBOILING – This involves the treatment of the Paddy with hot water, it could be boiling the paddy for about 20 minutes. This could increase the quality of Rice from 60 – 70% in Hulling. The advantage of Parboiling is that it causes some of the Vitamin B from part of the grains to migrate into the inner endosperm consequently improving the nutritional quality value of the milled rice. After Parboiling, the paddy is dried and set ready for hulling.

HULLING

This is the removal of the pericarp or the husk. The paddy is fed into the centre horizontally disk that are covered with rough emery for effective dehulling which are separated from the rice grains by series of sieves and blower to separate the hulled rice.

PEARLING

There are various set of Cones ensuring the husk removal.

This is the removal of the Aleuron layer through a series of Pearling Cones. As this goes on the rice is milled and the bran is pushed through the interstices of the wirecloth.

POLISHING OR BRUSHING

To obtain a really fine white rice, the rice is passed through further series of polishers . Sometimes when a particular sophisticated degree of whiteness and smoothness is required a small amount of talc (Calcium) is added when going to the final polisher. It should be noted that the rich bran is removed for aesthetic (whiteness ) .

COMMERCIAL VIABILITY OF RICE MILLING

During milling, about 45% of the husk is removed from the rice grain. The husk removed is used for animal feeds .

USES

- Human consumption rice grains are milled and boiled for human consumption, however it is of inferior nutritive quality and diet bared mainly on white rice leads to Beriberi (deficiency of vitamin B)

- Rice is used for thickening eg on cooking fish, addition of rice flour thickens the fish for firm texture. (Starch presence )

- Rice paddy is used for Poultry feeds and other Livestock.

- Rice flour meal can be included in the ration for livestock .

- Rice straw is used as maintaince ration for livestock. ,although excessive feeding on this may inhibit the absorption of Calcium due to the presence of Oxalic acid..

At WUFAS AGR0Net, We are Competent and Reliable Food Processing Technologists into Human Capital Development Consultancy in Food Processing Technology enhancing Global Competitiveness and International Best Practices for the teeming youthful population, unemployed graduates, propreneurs and other Food handlers through our Entrepreneurial / Empowerment Demonstrative Seminars in FOOD PROCESSING TECHNOLOGY. FOR further detailed enquiry on Rice milling Contact us today for CONSULTATION. Can 08157784430, 08034064270 Fb pages WUFAS AGR0Net. Email us wufasagronet@gmail.com.

Uncategorized

BUSINESS ANALYSIS OF BASIC WATER PRODUCTION (BOTTLES/SATCHET ). Consultancy services.

—- Business registeration (CAC).

—- NAFDAC : Requirements for Production Premises .

● Inspection fees

● Lab. Analysis

● License fees

Vat inclusive.

■ Factory premises.

■ Water Treatment Plant & Borehole

■ Production Machinery.

■ Filtration materials

■ Industrial Generator \ Solar arrangements.

■Distribution Vehicles

■ Staff salary and emoluments.

■ Packaging materials (pet bottles or satchet rolls )

■ Consultation fees ( very reasonable and in consonant with the economic realities).

These are areas of costing (Cost centers).

Good day.

…..@ WufasAgronet, We are Competent and Reliable Advocates in Food Security (Process) .

Contact us @ email : wufasagronet@gmail.com or

www.wufasagronet.com

-

Food Security4 years ago

Food Security4 years agoREALITIES OF LARGE SCALE INTEGRATED AGROPRENUERAIL FARMING AND FOOD PROCESSING BUSINESS IN NIGERIA. (Update)

-

Environmental3 years ago

Environmental3 years agoOPINION: AN ACCESSMENT OF NIGERIA’S PERFORMANCE IN THE OPTICS OF THE UN 17 SUSTAINABLE DEVELOPMENT GOALS AGENDA 2030. ( Periodic quaterly review & update — ( September ’22)

-

Food Security4 years ago

Food Security4 years agoEXCITING FACTS ABOUT RANCHING

-

Food Security3 years ago

Food Security3 years agoTOP SEVEN AGRICULTURAL COMMODITIES WITH HUGE UNTAPPED POTENTIALs – update

-

Food Security3 years ago

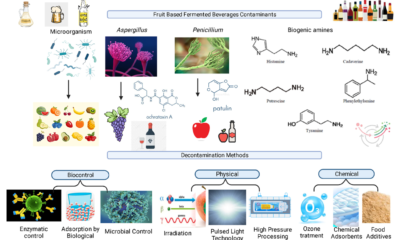

Food Security3 years agoMICROBIOLOGICAL AND CHEMICAL EVALUATION OF LOCALLY FERMENTED BEVERAGES — PITO & BURUKUTU

-

Food Security4 years ago

Food Security4 years agoMITIGATING THE MENACE OF CLIMATE CHANGE THROUGH GREENBOND ISSUANCE.

-

Food Security4 years ago

Food Security4 years agoFISH PROCESSING TECHNOLOGY

-

Food Security4 years ago

Food Security4 years agoTHE ROLE OF E -COMMERCE IN SYNERGISING AGRICULTURAL VALUE CHAIN DEVELOPMENT IN AFCTA IS SINE QUA-NON.