Food Security

ESPOUSING THE NEW CASSAVA VARIETIES AND INDUSTRIAL VALUE CHAIN

.

…… @ WUFAS AGRONET, . — We don’t know more than Food.—- ( Earner ” FAO TOP FAN Badge ” )

CASSAVA YIELD .

The low root yeild of Cassava per hectare in Africa is unacceptable. Africa account for 55% of global production yet Africa’s yield per hectare is the lowest in the world about 10metric tons per hectare compared with Asia’s yield of 21metric tons per hectare doubling Africa’s.

WAY OUT:

Reversing the current trajectory on cassava low yield would demand deliberate steps including

— Investment on research and innovation,

— Favourable policy framework,

— Accessibility of loans to farmers at single digits rate and

— Mechanisation.

■ DEVELOPMENT OF NEW CASSAVA VARIETIES

Concerted R&D (IITA) efforts are yielding the desired results as “Next Gen Project” has come up with two varieties of cassava known as Baba 70 and Game changer. At demonstration farms in Kogi/Benue states The new species yielded more than the local varieties producing more than 30t/hre with large size and number of roots instead of average yield of 8 -11t/hre. The Game Changer produces 30t/h while Baba 70 produced 38t/h both are drought tolerance and resistance to virus diseases of cassava. In addition to high yield and stress tolerance , they’re equally suitable for several agro- ecologies , To the farmets the high yielding and stress tolerant had the right food properties that will raise the livelihood of farmers with high profit and make huge contribution to Food Security as compared more favourably against TME 419.

CASSAVA VITAMIN A ( TME 419 ) .

● Hitherto, Vit. A enriched (TME 419 code 07/0593) This cassava contains high level of Beta carotene a precursor of Vit A.

— Cassava contains about 80% Carbohydrates (on table) if not properly complimented with other nutrients it’s excessive consumption may result in impaired vision or blindness and other terminal sicknesses.

—-Cassava is raw material for processed food, animal feed and other industrial cassava value chain . It’s used as adjunct with wheat flour for bread and other pasteries. In human consumption, it produces over 500 calories fairly making it important Food security crops.

MECHANISATION:

It is rather sad that Nigeria is not in the league of mechanized farming Nation. Presently, tractor usage is below 50 unit per 1000km of farm land as against 300 unit per 1000 km per farmland in developed economy nations . More statistically placed, Nigeria is one of the least mechanised farming nation in the world, with tractor density estimated at 0.27 hp/hectare far below FAO recommended tractor density of 1.5 hp/ hectare. Nigeria is 132nd out of 188 countries worldwide (FAO /UN tractors evaluation ) This is the reason why farming has been on subsistence level rather than commercial. Nigeria need $3 trillion to bridge the huge infrastructural gap as reported by Global Rating Agency -(Moody investors services ).

However, the Federal government of Nigeria recently (February 2021) reduced vehicles tariff (including tractors ) by 30%. This may cushion the effects of inflation currently at about 25.7% and improve the tractors density.

Africa needs to scale out proven technologies which include

■ The recommendation on weed control as developed by cassava weed management control project,

■ Improved cassava varieties and the best bet agronomy practices such as appropriate fertilizer application,

■ Also there need to be a synergy between the policy makers and cassava scientists to be aware of existing technologies to transform cassava to an enviable economic crop and create environment for exchange of technical, scientific agricultural, industrial and economic information on cassava among the stakeholders like scientists , farmers, processors, end users , the private sector and donor agencies .

● It is important to maintain the policy initiative with sustainable institutional framework to avoid the problem of policy summersault .

■ Activities of cassava research and development will unlock the potentials of cassava in food security and create wealth for Processors, Transporters, Marketers and Packaging enterprises , and sustainable Food security.

-■- As Nigeria grapples with current scarcity of wheat, As a stakeholder in Food Security (@Wufasagronet), this could be averted if cassava production supply is able to meet the huge demand.

However, scarcity of cassava tuber remains a challenge . Production of cassava is principally in the hands of smallholder farmers producing for home consumption and unable to meet huge demand . For instance to produce cassava bread takes cassava of 20% as an adjunct to wheat flour this local demand could not be achieved.

Government need to map out support to farmers on fertilizer amongst others.

● While the apathy to cassava bread can be assuaged by continuous education to sustain acceptability.

The lesson learnt from the above is the effective use of Science Technology / Innovation STI to ensure that our self sufficiency is ensured and territorial integrity is protected.

CASSAVA VALUE CHAIN DEVELOPMENT.

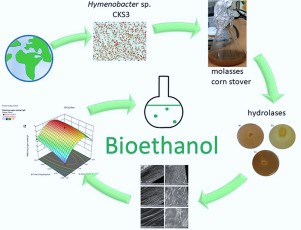

Amongst many other operators, Industrial applications of Starch include : Pharmaceutical, textiles, bakeries, beverages, distilleries and other food sector operators depends on cassava value chain such as Starch, sweeteners ethanol, bakers yeast, caramel, HQCF ( high quality cassava flour)

Presently as it stand, which is very unacceptable,

Nigeria is importing.

— 96% of 600,00mt of starch. ,applications includes adjunct for wheat flour in pastries.

— 100% of 200,000mt. of Sweetners

— 88% of 504000mt of HQCF.(Pharmaceuticals ).

— 98% Ethanol. (Potable and Industrial. )

— 100% of Bakers yeast imported.

While domestic application as Food takes about 60% of African menu eg: Garri, Fufu, Cassada, Starch Others include Livestock feed etc

● A do nothing approach on cassava value chain left fully untapped is dangerous , as mentioned above .

The policy makers, Scientists, processors. must synergize to create the great wealth cassava is presenting us in Nigeria and indeed Africa.

AT WUFAS AGRONET – WE ARE FOOD PROCESSORS INTO HUMAN CAPITAL DEVELOPMENT CONSULTANCY.

At : WUFAS AGR0Net We are processors who are vast and experienced in Saccharification./ Hyrolyses process which is breaking down of polysaccharides into mono and disaccharide with further processing can produce like ethanol, sweetener ,glucose syrup etc.

While cassava flour can also be gotten through flash dryer these and lot more are what we want to disseminate to teeming entrepreneurs.

At WUFAS AGR0Net we are Competent and Reliable Food Processing Technologists into Human Capital Development Consultancy in Food Processing Technology enhancing Global Competitiveness and International Best Practices for the teeming youthful population and other Food handlers.

Contact us today 08034064270, 08157784430 email -wufasagronet@gmail.com Fb WUFAS AGRONET.

Food Security

SECURITY PATHWAYS IN RELATION TO SUSTAINABLE FOOD SECURITY OF A NATION.

Good governance is predicated on ensuring the actualisation of the various security architecture of a Nation. The political barometer is also monitored through the efficiency of the security pathways which are :

INTERNAL SECURITY, INFORMATION/COMMUNICATION. , FOOD SECURITY, HEALTH ,EDUCATION, ELECTRICITY, TRANSPORTATION AND INDUSTRIAL GROWTH.

.

All the above are the essential security systems that can produce and provide QUALITY POPULATION through good and quality SUPERVISION

✅NATIONAL Security of life and properties is the (numero uno) number one responsibility of the Head of government be it President, Head of state and others. The mandate to secure life and property is paramount , they control and command the apparatus of security such as adequate Policing, effective Armed forces- Army for protection against external or internal aggression. Customs / Immigration for vigilant boarders patrol to prevent smuggling and immigration control amongst many others . Equipping them with weapons, Aircrafts, Vehicles, Boats etc.

For effective surveillance. In tackling the menace of bandits and kidnappers who have taken over the forest prohibiting farming activities . Armed Forest Guards / Rangers should be introduced.

INFORMATION/COMMUNICATION.

The entire world is in information age.

The constitution clearly stipulate that every person shall be entitled to freedom of expression, freedom to hold opinions and to receive as well as to impact ideas and information.

However, it is the opinion of this writer that freedom be guided with secured intent to prevent abuse that may result in conflicts and war through hateful and unguided utterances.

The most acceptable form of communication is such that promote humane, responsible and patriotic reportage upholding the concept of discipline and promoting values nationally and internationally.

A lot of opportunity mostly untapped abound for investment in Information and communication like Print, Electronic and ICT media.

For industrial growth, information through advertisement, publication and social media is vital for public awareness.

FOOD SECURITY

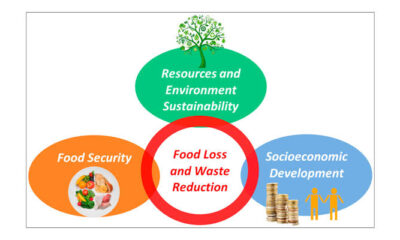

Whether one eat to live or live to eat is a matter of semantics the bottom – line is Food is the main sustainace of bodies and souls. The importance of food cannot be over emphasised . knowing this fact of life has made the developed world to appropriately plan for provision of quality food for their citizens. Provision of food is prioritize in their national agenda. It is on this note that the United Nation’s clarion call to others in the world to emulate the culture of Sustainable Food Security ensuring the Tripple A(s). of AVAILABILITY, ACCEPTABLITY and AFFORDABILITY. ( UN 2030 food security agenda) of good quality food for the underdeveloped countries who are import dependent on basic food items such as Rice, Sugar, Dairy , Beverages etc .

Presently, Nigeria is revolutionising agrioprenuerial activities, it’s hoped that the present policies on agriculture will not be Summersaulted. The Maputo declaration on allocation of minimum 10% of the country’s annual budget must go to agriculture. Food must be made a constitutional right for all. The authority must take time to support Micro and Small scale Agroprenuerails activities to adapt to climate change. Agroprenuerail activities is the surest way to lift hundreds of millions out of hunger, poverty, conflict and deaspiration.

HEALTH CARE

Health is wealth – Primary Health care delivery must be taken to the grassroot levels, while Rural Health care moblisation be made available and effective all must be well equipped with vaccines, drugs, consumables and other biologicals.

— Ensure maintenance of standard by private sector through effective monitoring.

— Tapping into Herbs Processing , local medical herbs be Researched into by National Institute of Pharmaceutical RnD. In Collaboration with Fed Mins. of Science and Technology.

— Integration of alternative medicine into health care.

— Health insurance scheme must be intensified on .

— Stemming of illegal importation of smuggled fake drugs and illegal drug manufacturing in the country.

EDUCATION

A Society, Community and Nation is as good as the percentage of her literary population. The various levels of education are Primary , Secondary and teriary education 6-3-3-4 .Education must attract appropriate budget at all time. Education is being administered by Public and Private participation at all levels. The special education must receive attention by provision of special equipment such as braille machine, audiometer etc.

ELECTRICITY

To the chagrin of the unsuspecting consumers and Contrary to claim of the generation companies that generation capacity has improved to 7000 MW , the actual has been fluctuating between 2500 -3500 MW.(April 2019)

The idea of mono grid must be jettison while the legislation be relaxed to accommodate Private participations in generation. While effort must be intensified on the Green Bond of #10.97bn raise in December 2018. for financing of SOLAR energy.

Industrial development is unachievable without steady supply of electricity. A green belt of

Industrial Parks on Green energy is recommended in all the States of federation.this will sustain industrial activities that will promote growth.

TRANSPORTATION

This sector is an indispensable catalyst for stimulating economic, social, political and strategic/defence development of a Nation. All the National Development plans must accord the transport sector very high priority. In the formulation of National Transport policy, there must be defined objectives such as economic efficiency and coordinated development plan.

All forms of transportation system are embraced in Nigeria. Motor ,Railway transportation, inland waterways, aviation terminal and handling facilities seaports, airports and riverports including other ancillary facilities.

The administration of Transportation is vested in both Fed. Ministry of Works and Housing (Fed. Highways – Interstate roads Construction and maintenance) and State Ministry of Works/Transport (interstate roads while LG is responsible for Urban and Rural roads Construction and maintenance.

Aviation Ministry for Civil Aviation, Airports Development Management and Metrological services.

Internationally, the railway system is more affordable and relatively saver the frequency in Nigeria must be upgraded not scanty show up as is now the case.

INDUSTRIAL GROWTH

The economic growth rate ( 2019) is 2.1% ,this development is not unconnected with the dismal performances of the various indices above. eg the manufacturing growth rate is presently less than 7% although the Fedreral government set a 10.6% goal in 2017.which was to be driven by SME. Productivity is the only stimulant for Industrial growth. Farming output is barely about 22% mostly subsistence. .about 55% of work force is absorbed by agriculture. The major farming communities in North East, Middle belt downwards to the southern section are being sacked either Boko Haram terrorist or Pasteuralist /Farmers conflicts and banditry.

The various activities as enumerated in this writeup are all depended on Food security system. FOOD SECURITY MUST BE IN THE FRONT BURNER TO ACHIEVE SUCCESS. IN OTHER SEGMENTS.

CONCLUSION

— FOOD Security issues must be in the front burner of government’s agenda. Since it encompasses all other activities.

— The effectiveness of other parasatal must be ensured through adequate supervision.

— TO PREVENT IMMINENT DANGER OF FAMINE. Forest Guards (armed) must be appropriately deployed to secure the large expanse of the forest for Farming activities.

— Indigenous Reserch and Development on local Technology be improved on.

— Electricity generation from Green Energy source should be encouraged in the Industrial parks.

— Food Security system must be made a CONSTITUTIONAL RIGHT for all the citizenry.

At WUFAS AGR0Net, we are Competent and Reliable Food Processing Technologists ,into Human Capital Development Consultancy. Centering on ETHICS of Food Processing Technology. Training on industrial food processing (General Manufacturing Principles ) to the teeming youthful population, startups and other Food handlers. We are seeking Collaboration and Strategic partnership with corporate bodies, NGOs and others

Interested in Food Security.

Contact: 08157784430, 08034064270.

Emails wufasagronet @gmail.com

Food Security

BIO-ETHANOL DISTILLATION PROCESS.(using molasses)

✅—– by (WUFAS AGR0Net fmr. Factory Mgr.Nig. Yeast & Alcohol Manu.co.Ltd. (NIYAMCO).

Ethanol Distillation plant Bacita kw.state )

ALCOHOLS .

Portable Ethanol production using molasses is a product of (anaerobic ) fermentation , the process brings about multiplicity of products such as Methanol, Ethanol(C6H5OH ), Butanol, Penthanol and other higher Alcohols. Distillation is a process of specificity each of the Alcohols have their flash or boiling points at which they’re separated in the distillation column.

MOLASSES PREPARATION .

Molasses is a very viscose syrup a waste product of crystalline sugar from sugar manufacturing plant. It consist of about 80% sucrose and other metallic ions eg ferrous, calcium, magnesium, Mercury etc. with caramelised sugars.

At the plant the viscose molasses is charged into a large mixing vat with enough water to bring down the viscosity to the desired ( brix) or density usually from about 40deg.brix to 14deg brix. Then heat is applied to about 80 deg.cent. while agitation continues. the solution is treated with sulphuric acid (H2SO4) and Urea an ammonium salt. While the acid form the sulphate salt of the metallic ions and precipitate the ammonia serves as nutrients for the yeast during fermentation. At the desired density the solution is transferred into the fermenter through plate heat exchanger that cools the molasses solution to ambient temperature. While simultaneously the solution is pitched with yeast from the cold yeast vat.

CASSAVA is another potent source of Ethanol fermentation by degradation of the polysaccharide into simple sugars. — Comprehensive details in our journal.

FERMENTATION

The fermenter is of stainless steel and double jacketed. (For temperature control ). Fermentation is left for about 8-10hr till the density comes down to ( 6 + or -2 )

The yeast is then purged via the centrifuge back to the cold storage awaiting the next operation. While the fermented wort goes to the wort Buffer Stock tank ready for distillation.

YEAST .

The Yeast is propagated by BUDDING process. While the yeast room is kept clean at very low temperature.

QUALITY CONTROL

The quantity of alochol in the fermented wort can be determined prior to distillation in the laboratory as would be explained the journals.

DISTILLATION

Distillation is the separation of components of a solution based on their volatilities. (Dalton’s law)

The material for distillation is charged into the batch or continuous column equipped with the followings :

— Overhead vapour line.

— A condenser

— A condensate receiver

— Gravity separators

— Steam is admitted through perforated pipe at the bottom.

The performance of the plate column is based on Material balance, Energy balance and Phase equilibrium .

Hence Total Material .Balance is represented by the equation

F=D+B

F— Feed

D— separated vapour

B—-Bottom product.

Factors influencing plate efficiency for satisfactory separation are:

— Adequate operation of the plate.

— Adequate and intimate contact between vapour and liquid is very essential.

–Avoid excessive foaming or entrainment.

— Avoid poor vapour distribution.

— Avoid short circuiting or weeping.

— Avoid liquid dumping.

All these lower plate efficiency. Plate efficiency is a function of Mass transfer between liquid and vapour.

At 80deg.cent boiling point of Ethanol it will separate out and the condensate cooled and sent to the stock tank given Potable Ethanol of about 97%. While the higher Alcohols Methanol, Butanol, Penthanol etc are received in another stock tank these combination is called Industrial Alcohols. Used as solvent industrially.

The above is a brief elucidation of the distillation process which is frothy with illustrative linearity equations. For further interest contact us for full details.

At WUFAS AGRONET, WE ARE COMPETENT AND RELIABLE FOOD PROCESSING TECHNOLOGISTS INTO HUMAN CAPITAL DEVELOPMENT CONSULTANCY IN FOOD PROCESSING TECHNOLOGY PROMOTING GLOBAL COMPETITIVENESS AND INTERNATIONAL BEST PRACTICES IN FOOD PROCESSING TECHNOLOGY .WE SEEK COLLABORATION AND STRATEGIC PARTNERSHIP WITH NATIONAL AND INTERNATIONAL STAKE HOLDERS IN FOOD SECURITY SUCH AS WORLD BANK, USAID, NGOS. IN training the teeming youthful population in productive ventures of Food Processing Technology.

Contact : 08034064270, 08157784430.

Email, wufasagronet@gmail.com

Food Security

FOOD SECURITY AND IT’S ATTENDANT GLOBAL CRISIS – WORLD BANK GROUP REPORT.

✅ The World bank had given analytical database information on Food Insecurity.

✅Food Insecurity cannot be localized to the leadership of any country.

….. @WufasAgronet, we are competent and reliable Food Technologists into Human Capital and Value Chain Development Consultancy.

The latest Food Security Update is now available here: http://wrld.bg/NZ9C50UsKBg

Uh

Highlights:

➡Domestic food price inflation remains high in many low- and middle-income countries. Inflation higher than 5% is experienced in 68.8% of low-income countries, 46.7% of lower-middle-income countries, 33% of upper-middle-income countries, and 10.9% of high-income countries.

➡ Since the last Update on November 15, the agricultural, export, and cereal price indices closed 12, 25, and 1 percent higher, respectively. A sharp increase in cocoa and coffee prices drove the increase in the export price index.

➡In the Market Monitor for December 2024, the Agriculture Market Information System notes that global wheat, maize, rice, and soybean prices are lower than in 2023. This reflects a relatively stable global market for the current marketing season, although uncertainties linger.

➡In the November 2024 edition of its biannual Food Outlook, FAO indicates that global food production is experiencing diverse trends across commodities. Declines are projected for wheat, maize, and sugar, whereas outputs of dairy, fisheries, meats, oilseeds, and rice are expected to grow.

➡According to the WFP’s 2025 Global Outlook, an estimated 343 million people are acutely food insecure across 74 countries where WFP operates—10% more than in 2023.The latest Food Security Update is now available here: http://wrld.bg/NZ9C50UsKBg

Highlights:

➡Domestic food price inflation remains high in many low- and middle-income countries. Inflation higher than 5% is experienced in 68.8% of low-income countries, 46.7% of lower-middle-income countries, 33% of upper-middle-income countries, and 10.9% of high-income countries.

➡ Since the last Update on November 15, the agricultural, export, and cereal price indices closed 12, 25, and 1 percent higher, respectively. A sharp increase in cocoa and coffee prices drove the increase in the export price index.

➡In the Market Monitor for December 2024, the Agriculture Market Information System notes that global wheat, maize, rice, and soybean prices are lower than in 2023. This reflects a relatively stable global market for the current marketing season, although uncertainties linger.

➡In the November 2024 edition of its biannual Food Outlook, FAO indicates that global food production is experiencing diverse trends across commodities. Declines are projected for wheat, maize, and sugar, whereas outputs of dairy, fisheries, meats, oilseeds, and rice are expected to grow.

➡According to the WFP’s 2025 Global Outlook, an estimated 343 million people are acutely food insecure across 74 countries where WFP operates—10% more than in 2023.

AT WUFASAGRONET, We aren’t the author of the above we are only making the report available to the grassroots.

-

Environmental3 years ago

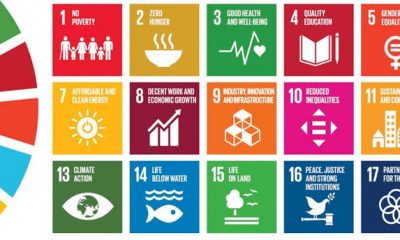

Environmental3 years agoOPINION: AN ACCESSMENT OF NIGERIA’S PERFORMANCE IN THE OPTICS OF THE UN 17 SUSTAINABLE DEVELOPMENT GOALS AGENDA 2030. ( Periodic quaterly review & update — ( September ’22)

-

Food Security3 years ago

Food Security3 years agoREALITIES OF LARGE SCALE INTEGRATED AGROPRENUERAIL FARMING AND FOOD PROCESSING BUSINESS IN NIGERIA. (Update)

-

Food Security3 years ago

Food Security3 years agoEXCITING FACTS ABOUT RANCHING

-

Food Security3 years ago

Food Security3 years agoTOP SEVEN AGRICULTURAL COMMODITIES WITH HUGE UNTAPPED POTENTIALs – update

-

Food Security3 years ago

Food Security3 years agoMITIGATING THE MENACE OF CLIMATE CHANGE THROUGH GREENBOND ISSUANCE.

-

Food Security3 years ago

Food Security3 years agoFISH PROCESSING TECHNOLOGY

-

Food Security3 years ago

Food Security3 years agoTHE IMPENDING GLOBAL FAMINE FROM THE PERSPECTIVES OF THE WORLD INSTITUTIONAL LEADERS.

-

Food Security3 years ago

Food Security3 years agoTHE ROLE OF E -COMMERCE IN SYNERGISING AGRICULTURAL VALUE CHAIN DEVELOPMENT IN AFCTA IS SINE QUA-NON.