Food Security

FEASIBILITY STUDY ON RANCHING MODERN ANIMAL HUSBANDRY

■ Ekiti State Govt. In 2021 imported 250 cows from the USA. The State is now into daily milk production of about….

…. AT WUFAS AGRONET, We don’t know more than food.

We earned “FAO” Top Fan barge.

■ COMPETENT AND RELIABLE FOOD PROCESSING TECHNOLOGISTS IN HUMAN CAPITAL DEVELOPMENT CONSULTANCY. WITH SPECIAL BIASE IN “RANCHING SYSTEMS AND TECHNOLOGY.”

Animal ranching is the modern-day form of animal husbandry in a stable ( building in which domestic animals are sheltered and fed.) Animals are individually stationed in a pen or cage in a row of other animals. The total land space could be about 500 hectares for a minimum of 1000 Cattles.

This confinement of animals makes it possible to give holistic care for the animals such as Inspection, Feeding, Lairage, Milking, Crossbreeding, and Veterinary care among others.

INSPECTION

General appearance of the animals eg. Possibility of diseases in an old emaciated cow is greater than in a well finished prime young animals.

- Temperature should be 38.5°C.

- The Ear, Hoof, and Horn should be cool to touch. The eyes should be bright and clear.

- Irritability, animals should be alert and attempt to move if approached.

- The animals should not bear patches or signs of parasitical conditions.

- Breathing should be steady and regular

- If any, cough can be induced by pinching the lynx.

- No offensive discharges, Urine should be a straw color not cloudy, and in a strong continuous discharge.

- The animals are regularly vaccinated to prevent the spread of transborder diseases.

FEEDING

- Herbage / hay / straw – These are grass fodder . This provides job opportunities for Herbagers from improved herbs species.

- Molasses, this is a sucrose waste from sugar factories. Molasses is given to produce glucose in the body which can be oxidised to Yeild milk. It’s energy given ration usually dissolved in the drinking water of the cows.

- Calcium for strong Bones.

- Water , excess water is given to wash the intestine to reduce microbial flora.

LAIRAGE

This is a stage of rest to rejuvenate the animals.

CROSS BREEDING

- Local breed ( Bunaji)can produce only about 4- 6 kilos of milk per day which is barely enough to feed their calves leaving nothing over for processing. While imported Holstein Frisian heifers can produce about 35kg of milk per day.

- With artificial insemination to crossbreed the foreign with the local the level of milk secretion will surely improve while the beef quality could match the export quality range.

MILKING

Currently, + Nigeria is not in the league of Dairy producing countries of the world making her to be massively import dependent nation on dairy products which are by far more profitable than beef we consume locally with no foreign exchange attraction.

Dairy products will attract Technology that is currently not in existence such as necessary infrastructure to support large cold storage facilities at various locations for the highly perishable milk.

- Refrigerated transportation system for the collection of fresh milk from point to point.

- Network of distribution system for products with low shelf life. etc.

VETERINARY SURGEON

Attending to animals health care.

The aforementioned are various jobs opportunities and many more that modern-day ranching will attract..

CONCLUSION

Ranching will reduce the farmers -Ranchers clashes

Ranching will reduce high cost of doing business with bringing and keeping the expatriate staff in our dairy companies.

Reduction of foreign exchange sourcing for dairy products.

At WUFAS AGR0Net, We are Competent and Reliable Food Processing Technologists into Human Capital Development Consultancy in Food Processing Technology enhancing Global Competitiveness and International Best Practices for the teeming youthful population, unemployed graduates, propreneurs and other Food handlers.

WE HAVE SPECIAL BIASE IN “RANCHING SYSTEMS AND TECHNOLOGY “

Contact us today for CONSULTATION ON RANCHING SYSTEMS AND TECHNOLOGY.

OUR Contact 08034064270 , 08157784430.

Food Security

CHARACTERISTICS OF GOOD DETERGENT

CHARACTERISTICS OF GOOD DETERGENT

www.wufasagronet.com

….. @WufasAgronet, we are Food Security (processing) Advocates.

✅Earned FAO, WFP, WORLD BANK, IFAD, IDA, IMF, UNSDGs, USAID, ROCKEFELLER FOUNDATIONS, BBC NEWS, JAGABAN ARMY, PUNCH NEWSPAPERS, GUARDIAN Newspapers, Today Reporters, Ripples News etc TopFan Barges.

✅Member NAAJ, PAAJ, IFAJ AND AFAN.

✅Consultancy Services in Human Capital and Value Chain Development in Food Processing technology.

DETERGENTS used for washing in industries should have the following characteristics.

-Ability to loosen organic matters eg. Soil etc. (organic dissolving power)

-Good rinsing power.

-Adequate wetting power to allow detergent to penetrate the deposit acting quickly and efficiently.

-Good sequestering power – removal of mineral deposits eg. Calcium, magnesium.

-Emulsifying power – fragmenting oil into tiny particles.

-Adequate germicidal power to sterilized dirty detergent solutions.

-Ability to dissolve alkali solutions precipitate of calcium and magnesium salt.

-It should not be corrosive.

-It should posses good buffering and saponifying powers.

The above characters may not be contained in a single detergent but if blended with others rich in some of the characters, a good result may be achieved.

MAJOR SOURCES OF DETERGENTS.

{Alkalis} – Caustic soda is the basic ingredient of detergent however,

there could be addition of other additives to give a property to the detergent. Other basic ingredients are Soda ash, Sodium silicate and others as seen above.

SEQUESTERING AGENT.

This is the action of polyphosphate in precipitation of calcium and magnesium salts in water creating additional wetting agent and polyphosphate to assist sequestration this would constitute most effective and economical clean-in-place detergent for brewing cleanings.

WETTING AGENT.

Known generally as synthetic detergent, Wetting agents are classified into 3 major types :An-ionic and Cat-ionic wetting agents.

The An-ionc type is commonly used for detergent formulation eg. Sulphated alcohols alkyl or aryl sulphonates. Non-ionic are mostly the polyethylonic oxide. On blending of both an ionic and catonic the result may be excessive foaming. It also processes good wetting, dispersing and rinsing power.

STERILISING AGENT.

Alkalis porcess sterilizing power, which increases with pH and temperature.

At WufasAgronet, we are competent and reliable Food Technologists into Human Capital and Value Chain Development Consultancy in Food Processing. Contact us email :wufasagronet@gmail.comPls go through the earlier sent documents.

Food Security

SEASONINGS. FLAVORS. FOOD INGREDIENTS.

✔Contact us @WufasAgronet for wide range of integrated flavors and seasonings, we are Manufacturers’ Representative.

…. @WufasAgronet we are Food Security (Processing) Advocates.

✅Earned FAO, WFP, WORLD BANK Group, UNSDGS, ROCKEFELLER FOUNDATIONS, BBC NEWS, JAGABAN ARMY, PUNCH NEWSPAPERS, GUARDIAN Newspapers, Today Reporters, Ripples News, etc TopFan Barges.

✅Member NAAJ, PAAJ, IFAJ & AFAN.

✅CONSULTANCY SERVICES IN HUMAN CAPITAL AND VALUE CHAIN DEVELOPMENT IN FOOD PROCESSING.

✔FLAVORS

BAKERY & PASTRY FLAVORS

*Vanilla flavor

*Condensed milk flavor

*Butter scotch flavor

*Enzyme chocolate flavor

*Enzyme butter flour

*Milk flavor

*Coconut flavor

✔ CONFECTIONERY & CANDY FLAVORS

*Strawberry flavor

*Chocolate flavor

*Orange flavor

*Butter vanilla flavor

*Banana flavor

*Mango flavor

*Lemon flavor

*Milk flavor

*Vanilla flavor

*Apple flavor

*Mixed berry flavor

*Coconut flavor

*Caramel flavor

*Honeydew flavor

*Condensed milk flavor

*Peanut flavor

*Cheese flavor

✔BEVERAGE FLAVORS

*Apple flavor

*Coconut flavor

*Caramel flavor

*Mango flavor

*Lemon flavor

*Banana flavor

*Pineapple Flavor

*Orange flavor *Strawberry flavor

*Natural Ginger flavor

*Malta flavor

*Grape flavor

*Raspberry flavor

✔ENCAPSULATED FLAVORS

*Strawberry flavor

*Raspberry flavor

*Mixed Berry flavor

*Orange flavor

*Apple flavor

*Banana flavor

✔BEVERAGES (CONCENTRATES, COMPOUNDS, BASES AND EMULSIONS) :

*Pineapple

*Lemon

*Ginger

*Cola

*Black currant

*Orange

*Strawberry

*Chapman

*Apple

*Banana

*Mixed fruit

*Cocopina

✔SAVOURY FLAVORS

*Beef flavor

*Chicken flavor

*Tomato flavor

*Cheese flavor

*Seafood flavor

*BBQ flavor

*Roasted flavor

*Smoked fish flavor

*Suya flavor

*Peanut flavor

*Roasted Chicken flavor

*Sardine flavor

*Smoke flavor

✔MILK POWDER :

*Fat filled milk powder

*Skimmed milk powder

*Full cream powder

*Flavored milk powder

*Butter milk powder

✔ICE-CREAM, YOGHURT & DAIRY FLAVORS :

*Yogurt flavor

*Vanilla flavor

*Strawberry flavor

*Banana flavor

*Mixed Berry flavor

*Chocolate flavor

*Cherry flavor

*Mango flavor

✔SEASONINGS:

FOOD SEASONINGS

*Beef seasoning

*Chicken seasoning

*Tomato seasoning

*Cheese seasoning

*BBQ Seasoning

*Seafood seasoning

*Noddles seasoning

*Pasta seasoning

*Jollof seasoning

✔SPICES :

*Cinnamon powder

*Onion powder

*Ginger powder

*Garlic powder

*Paprika powder

*Nutmeg powder

✔FOOD INGREDIENTS :

*Fat Replacer (Handisol – 25)

*Sweetener

✅OTHERS :

*Real meat reaction pastes

*Vegemeat for sausage roll

*Spice flavor oil

*Liquid and oil soluble flavor

*Soup and gravy mixes

*Ice cream premix

*BBQ sauce

*Tomato /Pizza sauce etc.

At WufasAgronet , we are competent and reliable Food Technologists into Human Capital and Value Chain Development Consultancy in Food Processing technology training the teeming youthful population including teirary institutions graduates in Global Competitiveness and International Best practices in Food Processing technology.

Contact email wufasagronet@gmail.com

Food Security

SECURITY PATHWAYS IN RELATION TO SUSTAINABLE FOOD SECURITY OF A NATION.

Good governance is predicated on ensuring the actualisation of the various security architecture of a Nation. The political barometer is also monitored through the efficiency of the security pathways which are :

INTERNAL SECURITY, INFORMATION/COMMUNICATION. , FOOD SECURITY, HEALTH ,EDUCATION, ELECTRICITY, TRANSPORTATION AND INDUSTRIAL GROWTH.

.

All the above are the essential security systems that can produce and provide QUALITY POPULATION through good and quality SUPERVISION

✅NATIONAL Security of life and properties is the (numero uno) number one responsibility of the Head of government be it President, Head of state and others. The mandate to secure life and property is paramount , they control and command the apparatus of security such as adequate Policing, effective Armed forces- Army for protection against external or internal aggression. Customs / Immigration for vigilant boarders patrol to prevent smuggling and immigration control amongst many others . Equipping them with weapons, Aircrafts, Vehicles, Boats etc.

For effective surveillance. In tackling the menace of bandits and kidnappers who have taken over the forest prohibiting farming activities . Armed Forest Guards / Rangers should be introduced.

INFORMATION/COMMUNICATION.

The entire world is in information age.

The constitution clearly stipulate that every person shall be entitled to freedom of expression, freedom to hold opinions and to receive as well as to impact ideas and information.

However, it is the opinion of this writer that freedom be guided with secured intent to prevent abuse that may result in conflicts and war through hateful and unguided utterances.

The most acceptable form of communication is such that promote humane, responsible and patriotic reportage upholding the concept of discipline and promoting values nationally and internationally.

A lot of opportunity mostly untapped abound for investment in Information and communication like Print, Electronic and ICT media.

For industrial growth, information through advertisement, publication and social media is vital for public awareness.

FOOD SECURITY

Whether one eat to live or live to eat is a matter of semantics the bottom – line is Food is the main sustainace of bodies and souls. The importance of food cannot be over emphasised . knowing this fact of life has made the developed world to appropriately plan for provision of quality food for their citizens. Provision of food is prioritize in their national agenda. It is on this note that the United Nation’s clarion call to others in the world to emulate the culture of Sustainable Food Security ensuring the Tripple A(s). of AVAILABILITY, ACCEPTABLITY and AFFORDABILITY. ( UN 2030 food security agenda) of good quality food for the underdeveloped countries who are import dependent on basic food items such as Rice, Sugar, Dairy , Beverages etc .

Presently, Nigeria is revolutionising agrioprenuerial activities, it’s hoped that the present policies on agriculture will not be Summersaulted. The Maputo declaration on allocation of minimum 10% of the country’s annual budget must go to agriculture. Food must be made a constitutional right for all. The authority must take time to support Micro and Small scale Agroprenuerails activities to adapt to climate change. Agroprenuerail activities is the surest way to lift hundreds of millions out of hunger, poverty, conflict and deaspiration.

HEALTH CARE

Health is wealth – Primary Health care delivery must be taken to the grassroot levels, while Rural Health care moblisation be made available and effective all must be well equipped with vaccines, drugs, consumables and other biologicals.

— Ensure maintenance of standard by private sector through effective monitoring.

— Tapping into Herbs Processing , local medical herbs be Researched into by National Institute of Pharmaceutical RnD. In Collaboration with Fed Mins. of Science and Technology.

— Integration of alternative medicine into health care.

— Health insurance scheme must be intensified on .

— Stemming of illegal importation of smuggled fake drugs and illegal drug manufacturing in the country.

EDUCATION

A Society, Community and Nation is as good as the percentage of her literary population. The various levels of education are Primary , Secondary and teriary education 6-3-3-4 .Education must attract appropriate budget at all time. Education is being administered by Public and Private participation at all levels. The special education must receive attention by provision of special equipment such as braille machine, audiometer etc.

ELECTRICITY

To the chagrin of the unsuspecting consumers and Contrary to claim of the generation companies that generation capacity has improved to 7000 MW , the actual has been fluctuating between 2500 -3500 MW.(April 2019)

The idea of mono grid must be jettison while the legislation be relaxed to accommodate Private participations in generation. While effort must be intensified on the Green Bond of #10.97bn raise in December 2018. for financing of SOLAR energy.

Industrial development is unachievable without steady supply of electricity. A green belt of

Industrial Parks on Green energy is recommended in all the States of federation.this will sustain industrial activities that will promote growth.

TRANSPORTATION

This sector is an indispensable catalyst for stimulating economic, social, political and strategic/defence development of a Nation. All the National Development plans must accord the transport sector very high priority. In the formulation of National Transport policy, there must be defined objectives such as economic efficiency and coordinated development plan.

All forms of transportation system are embraced in Nigeria. Motor ,Railway transportation, inland waterways, aviation terminal and handling facilities seaports, airports and riverports including other ancillary facilities.

The administration of Transportation is vested in both Fed. Ministry of Works and Housing (Fed. Highways – Interstate roads Construction and maintenance) and State Ministry of Works/Transport (interstate roads while LG is responsible for Urban and Rural roads Construction and maintenance.

Aviation Ministry for Civil Aviation, Airports Development Management and Metrological services.

Internationally, the railway system is more affordable and relatively saver the frequency in Nigeria must be upgraded not scanty show up as is now the case.

INDUSTRIAL GROWTH

The economic growth rate ( 2019) is 2.1% ,this development is not unconnected with the dismal performances of the various indices above. eg the manufacturing growth rate is presently less than 7% although the Fedreral government set a 10.6% goal in 2017.which was to be driven by SME. Productivity is the only stimulant for Industrial growth. Farming output is barely about 22% mostly subsistence. .about 55% of work force is absorbed by agriculture. The major farming communities in North East, Middle belt downwards to the southern section are being sacked either Boko Haram terrorist or Pasteuralist /Farmers conflicts and banditry.

The various activities as enumerated in this writeup are all depended on Food security system. FOOD SECURITY MUST BE IN THE FRONT BURNER TO ACHIEVE SUCCESS. IN OTHER SEGMENTS.

CONCLUSION

— FOOD Security issues must be in the front burner of government’s agenda. Since it encompasses all other activities.

— The effectiveness of other parasatal must be ensured through adequate supervision.

— TO PREVENT IMMINENT DANGER OF FAMINE. Forest Guards (armed) must be appropriately deployed to secure the large expanse of the forest for Farming activities.

— Indigenous Reserch and Development on local Technology be improved on.

— Electricity generation from Green Energy source should be encouraged in the Industrial parks.

— Food Security system must be made a CONSTITUTIONAL RIGHT for all the citizenry.

At WUFAS AGR0Net, we are Competent and Reliable Food Processing Technologists ,into Human Capital Development Consultancy. Centering on ETHICS of Food Processing Technology. Training on industrial food processing (General Manufacturing Principles ) to the teeming youthful population, startups and other Food handlers. We are seeking Collaboration and Strategic partnership with corporate bodies, NGOs and others

Interested in Food Security.

Contact: 08157784430, 08034064270.

Emails wufasagronet @gmail.com

-

Food Security4 years ago

Food Security4 years agoREALITIES OF LARGE SCALE INTEGRATED AGROPRENUERAIL FARMING AND FOOD PROCESSING BUSINESS IN NIGERIA. (Update)

-

Environmental3 years ago

Environmental3 years agoOPINION: AN ACCESSMENT OF NIGERIA’S PERFORMANCE IN THE OPTICS OF THE UN 17 SUSTAINABLE DEVELOPMENT GOALS AGENDA 2030. ( Periodic quaterly review & update — ( September ’22)

-

Food Security4 years ago

Food Security4 years agoEXCITING FACTS ABOUT RANCHING

-

Food Security3 years ago

Food Security3 years agoTOP SEVEN AGRICULTURAL COMMODITIES WITH HUGE UNTAPPED POTENTIALs – update

-

Food Security3 years ago

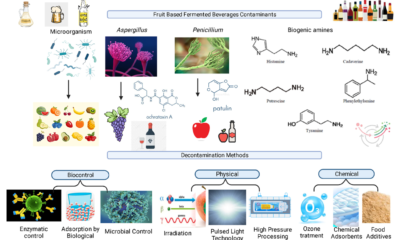

Food Security3 years agoMICROBIOLOGICAL AND CHEMICAL EVALUATION OF LOCALLY FERMENTED BEVERAGES — PITO & BURUKUTU

-

Food Security4 years ago

Food Security4 years agoMITIGATING THE MENACE OF CLIMATE CHANGE THROUGH GREENBOND ISSUANCE.

-

Food Security4 years ago

Food Security4 years agoFISH PROCESSING TECHNOLOGY

-

Food Security4 years ago

Food Security4 years agoTHE ROLE OF E -COMMERCE IN SYNERGISING AGRICULTURAL VALUE CHAIN DEVELOPMENT IN AFCTA IS SINE QUA-NON.